|

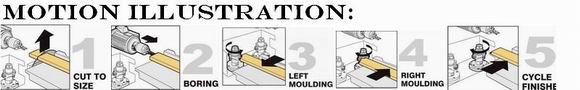

SINGLE SIDED CUTTING

BORING MOULDING MACHINE |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. The boring unit is driven by a 3HP motor. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2. One 5-spindles boring head is standard equipment. Other types of boring head are available upon request. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3. The boring unit moves on high precision liner guide ways for smooth trowel and high linear accuracy. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4. Boring head stroke is adjustable. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. The moulding units consists of two spindles, which run in opposite directions to avoid workpiece tearing duringmoulding operation. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2. One spindle is fixed, while the other spindle can be adjusted in height position. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3. The moulding unit is equipped with a see-thru guard to prevent chips from splashing. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. The machine eniploys two speed regulator knobs to adjust the table feed forward and backward speeds. Permitting workpiece contacting cutter smoothly. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2. Variable feed speed makes the machine ideal for cutting hard and soft wood. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3. The moulding units consists of two spindles. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4. One spindle is fixed, while the other one can be adjusted in height position. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5. The moulding unit is wquipped with a seethru guard to prevent chips from splashing. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Centralized control panel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. All motion controls of the machine are completely centralized on a control panel, providing operational convenience for operator. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electronic parts meet European standards | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. The control circuit in the electric cabinet consists of French TE brand electronic components, meeting European standards. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2. The high performance control circuit assure sensitive and stable motion controls at all times. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Miter gauge | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. The table is equipped with a miter gauge with angle setting 0 ~ 45 degree right and left, making the machine suitable for bevel molding operations. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2. The tabele is equipped with a 45 degree miter fence, allowing for cutting, boring, and moulding operation. Right and left 45 degree angular tenons can be accomplished at one time ( SK-TF-2 only ) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Air clamp | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1. The workpiece is clamped by air cylinder for convenient and fart clamping and unclamping. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

FEATURES

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |

||||||||||||||||||||||||||||||||||||||||||||||||||||||